Why should you prepare for 5G? Because you will be working with a 100% stable, reliable, secure and wireless connection, offering huge bandwidth that is up to 10 times faster than 4G. Moreover, unlike 4G, 5G makes it possible to establish a mobile connection with the same quality of service as your fixed network. In a production environment with many interfering elements (think of metal racks, for example), 5G performs better than Wi-Fi. So mobile devices and sensors can be used anywhere. With the large amount of data collected in real time, there is a constant monitoring of machines, which ensures process and product optimization.

A completely wireless production

Virtual, augmented and mixed reality

Improved communication in real time

Possibility to deploy drones

5G will facilitate the transition of your manufacturing business to smart factory, enabling you to take advantage of automation, artificial intelligence, augmented reality and IoT.

Make your production more intelligent and efficient

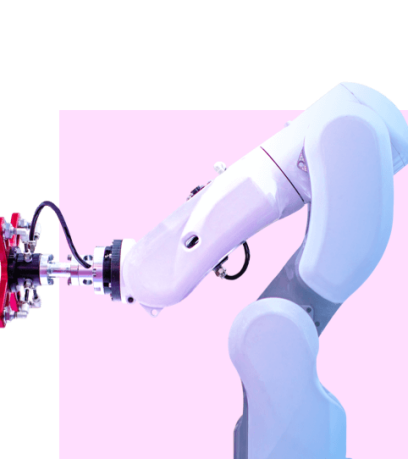

Program your production robots from one central location and control them from there in real time.

Do away with cabling for your devices, machines and sensors. Place them wherever you want.

5G allows for a wireless connection with the same quality of service as your fixed network.

A completely wireless production

Move objects from one place to another on your site.

Use the speed and maneuverability of drones for high altitude and hard to reach inspections of your installations, pipes or buildings.

5G offers very low latency which is crucial for drones. They respond almost instantly to an order from human pilots.

Possibility to deploy drones

Communicate easily with each other at all times, even if your colleague is working in another city or on another continent.

Take advantage of the high bandwidth and up to 10 times higher speed and improve your video calls with, for example, 3D, 360° and ultra HD, 4K or 5K streaming.

5G ensures mobile communication without a hitch during critical moments.

Improved communication in real time

Work together in real time with different people on product development in a virtual 3D space. Now you can see immediately in front of you what a colleague means or what your proposal changes about the plan.

Train your employees to work with a machine or production line in safe conditions. Simulate the situation with a VR or AR helmet or glasses so they can learn virtually.

Both VR, AR and MR require stringent network requirements such as low latency, high reliability and high bandwidth: requirements that 5G can provide.

Virtual, augmented and mixed reality

The Proximus NXT 5G innovation platform is a unique environment where you can validate your 5G projects in practice in cooperation with Proximus NXT. Gain experience before making further investments.

Do you have plans for a 5G project and need a test environment?

Improved communication in real time

A completely wireless production

Why should you prepare for 5G? Because you will be working with a 100% stable, reliable, secure and wireless connection, offering huge bandwidth that is up to 10 times faster than 4G. Moreover, unlike 4G, 5G makes it possible to establish a mobile connection with the same quality of service as your fixed network. In a production environment with many interfering elements (think of metal racks, for example), 5G performs better than Wi-Fi. So mobile devices and sensors can be used anywhere. With the large amount of data collected in real time, there is a constant monitoring of machines, which ensures process and product optimization.

Possibility to deploy drones

Virtual, augmented and mixed reality

5G will facilitate the transition of your manufacturing business to smart factory, enabling you to take advantage of automation, artificial intelligence, augmented reality and IoT.

Make your production more intelligent and efficient

A completely wireless production

5G allows for a wireless connection with the same quality of service as your fixed network.

Place sensors and cameras even in places where no wiring is possible.

Do away with cabling for your devices, machines and sensors. Place them wherever you want.

Program your production robots from one central location and control them from there in real time.

Possibility to deploy drones

5G offers very low latency which is crucial for drones. They respond almost instantly to an order from human pilots.

Automate your stock-taking.

Use the speed and maneuverability of drones for high altitude and hard to reach inspections of your installations, pipes or buildings.

Move objects from one place to another on your site.

Take advantage of the high bandwidth and up to 10 times higher speed and improve your video calls with, for example, 3D, 360° and ultra HD, 4K or 5K streaming.

Communicate easily with each other at all times, even if your colleague is working in another city or on another continent.

5G ensures mobile communication without a hitch during critical moments.

Improved communication in real time

Work together in real time with different people on product development in a virtual 3D space. Now you can see immediately in front of you what a colleague means or what your proposal changes about the plan.

Work interactively with your machines: get your machine data with a HoloLens, an AR helmet or glasses and view it on the screen in front of your eyes. This way, you have all the information you need about your machine at a glance.

Train your employees to work with a machine or production line in safe conditions. Simulate the situation with a VR or AR helmet or glasses so they can learn virtually.

Both VR, AR and MR require stringent network requirements such as low latency, high reliability and high bandwidth: requirements that 5G can provide.

Virtual, augmented and mixed reality

The Proximus NXT 5G innovation platform is a unique environment where you can validate your 5G projects in practice in cooperation with Proximus NXT. Gain experience before making further investments.

Do you have plans for a 5G project and need a test environment?

5G in transport and logistics

5G in public safety